Upgrade or Retrofit old Co2 Laser Machines or build new Laser Machines

(Agni is a Sanskrit word. It is the ‘Vedic fire of God’ capable of creating intense and focused heat.)

LinkMotion and AGNI Laser Controller are applicable to many different,new and used, CO2 laser machines.

This product is a combination of a special version of the LinkMotion driver designed to work with a special version of USB micro-laser controller.

LinkMotion driver is compatible with Windows 11, 10, 8 & 7 32/64, XP and 2000 operating systems. Additionally, it is compatible with many popular applications like Corel Draw, AutoCAD, DolphinCAD, AcceliCAD, PhotoShop, Corel Paint, Microsoft Word, and others. The job is designed and simply 'Printed' to the USB 2.0 high speed port for the ‘AGNI’ USB controller. Once set and initialized, LinkMotion hides in the background just like a regular printer driver.

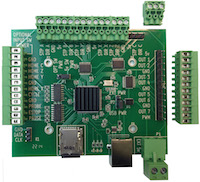

The USB micro-laser controller is a 2 inch X 2 inch size printed circuit board with a USB 2.0 compatible interface to connect to a PC. The controller handles up to 4 axis of operation with step/direction commands, 6 inputs, 8 outputs, separate connections for Home switches in each of the axis, and a number of I/O’s to handle all the requirements of a typical CO2 laser machine. It is the best retrofit/upgrade solution for existing laser machines. It is also the best controller for OEM’s interested in offering best in the features, functions, and the user experience.

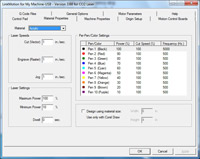

LinkMotion USB picks up appropriate Engrave (Raster) and Cut (Vector) information from the application when the job is printed to the driver. With the preset information for acceleration, resolution in each of the axis, color based settings for power, speed, and frequency, and process speeds, LinkMotion prepares and processes the job.

The numeric keypad of the PC keyboard is used as a Control Pad to jog the axis of the laser machine, position the laser beam, issue home command, repeat a job, decrease or increase the processing speed while the job is in process, pause and either quit or continue the job after pausing, check out the I/O’s, and other functions.

- LinkMotion driver software eliminates the need for learning any proprietary software to prepare a job for the laser machine.

- Upgrading features of the driver is as easy as installing the latest version of LinkMotion driver software on your PC.

- Many engraving and other businesses own older laser machinesthat may not have been upgraded/retrofitted for various reasons. LinkMotion and Agni Laser Controller may be helpful in retrofitting/upgrading these types of machines.

- Many engraving and other businesses are looking to purchase their first laser machine. LinkMotion and Agni Laser Controller may be helpful in finding a cost-effective solution.

- LinkMotion works with clip arts, logos, AutoCAD, graphics programs like Corel Draw!, and many popular programs for engraving and cutting with the greatest of ease.

- The return on investment for LinkMotion and Agni Laser Controller is very quick. While it offers many advance features, it pays for itself while processing just a few jobs.

- Design your job in one of the popular, off-the-shelf applications like Corel Draw, AutoCAD, Adobe Illustrator, and others......Simply Print and LinkMotion will send it to the laser machine equipped with the Agni laser controller.

- Corel Photo-Paint (part of the Corel suite) and PhotoGrav are excellent programs for the creation of 1-bit black and white dithered pictures with a choice of many filters.

- Once a job is designed, use the simple Print dialog box of the application to send the job to the laser machine using LinkMotion driver. There is no need to learn another application to communicate to the laser machine. There is no need to export the job file from one application to another. There is no reason to waste any time moving files back and forth.

- LinkMotion driver software and the micro-laser controller ‘AGNI’ are designed, developed, and manufactured right here in the USA.

- The power level is modulated as a function of XY axis speed when cut (vector) mode is active. This helps reducing the power at the corners when the machine needs to slow down and prevent the corners from burning. A minimum power level setting is available for each of the materials to make sure of the most appropriate power levels at the corners.

- Preset but expandable materials menu, positioning of a job, keyboard controls for axis moves, handling of the home position sensors, flexible start position, acceleration/deceleration setup and control, maximum step rate 125,000, 6 inputs, and 8 outputs are all part of the package.

- Older machines can be upgraded/retrofitted to work with Microsoft Windows' graphical interface and plethora of advantages can be had for your business. All of this is yours for a fraction of the cost of acquiring a new machine.

- Simple USB cable is all required and is included in the package to connect the PC to the laser machine.

- Specialized single line and multiline English language engraving fonts are offered optionally with accent marks for the European languages to perform fast and cost effective engraving jobs.

- Wired numeric keypads can be used to control the machine.

- All the documents and technical support are available locally and are available in the English language.

- LinkMotion and Agni Laser Controller are designed to work in inches or millimeters dimensions.

- Easy to customize configuration file for your machine including microstep resolution per millimeter for all 4 axis (X, Y, Z, and cylindrical axis), total working area, PWM laser frequency, and other settings.

- Cutting (vector) processing

- Engrave (raster) filled objects and bit map files with available selections of DPI resolution.

- PPI (pulses per inch) selection is available for engrave (raster) operations.

- Combined engrave (raster) and cut (vector) operations

- Setting of power, speed, and frequency by color for vector processing

- Tickle pulse setting for frequency and power, if required.

- Extremely convenient positioning of the job with respect to the design area in a program like Corel Draw and the working area of the laser machine. The output boundaries can be defined as either the plate size or the total working area of the machine.

- If the plate size of the job is smaller than the total working area of the machine, LinkMotion will prompt you for maximum possible multiple copies of the job. Multiple copies of the vector job will be processed one at a time.

- LinkMotion and Agni Laser Controller are capable of processing work on a cylindrical surface.

- Practically unlimited number of raster files (BMP) can be included in a single job. The upper limit is 1,016 raster files in a single job.

- Selection is available to process the raster jobs either from top to bottom or from bottom to top to work with the air flow.

- The laser power can be programmed and checked with the operation of a single key. This is a great feature for calibrating and re-tuning of the laser power source.

- Time to complete the job is displayed as soon as the job is transferred and the processing starts.

- Please, download the appropriate PDF file to understand the features in detail.